A flatbed truck the size of a small apartment? We'll make it!

written: 26.03.2025

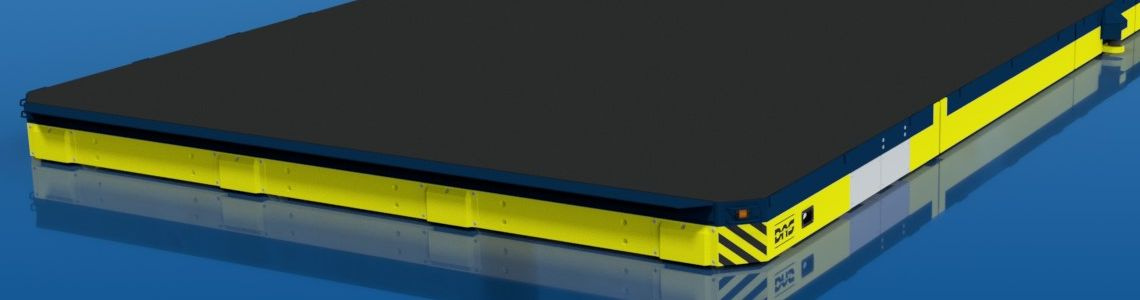

Custom-made flatbed truck can carry up to 42 tons

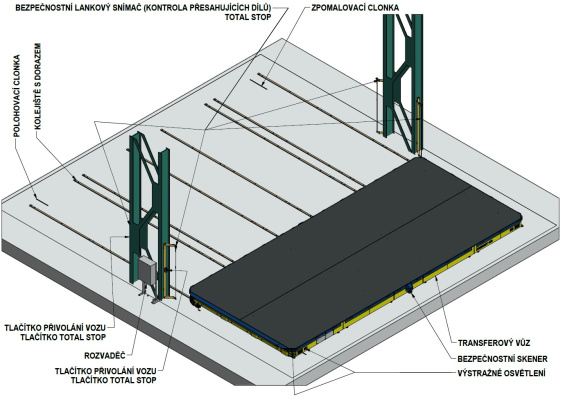

The largest Czech manufacturer of concrete reinforcements no longer had enough capacity in the hall where it stored finished products intended for shipping. Its production facilities are divided lengthwise into production sections with bridge cranes, but the main section was already being used to its maximum, so it was necessary to move finished orders to an adjacent part of the shipping hall.

To move finished fittings laterally, we designed a transfer car – a low platform with a platform measuring 5 × 11 m, creating one of our largest platform cars.

Railcar parameters:

- Load capacity: 42,000 kg

- Power input: 8 × 0.55 kW

- Travel speed: 0–15 m/min.

- Travel length: 7.5 m

- Loading area dimensions: 5,000 × 11,000 mm

- Loading area height: 350 mm

Modern technologies monitor every movement of the car

We pay great attention to safety, so the truck has several safety features. The two scanners that monitor the space in front of and behind the platform are absolutely crucial. When someone enters the truck's path, the device either slows down or stops completely. A wire sensor with a warning light also stops the truck if the material exceeds the length of the truck. Thanks to this, there is no risk of hitting any of the columns in the hall. In addition, the operator does not have to wait to find the activated sensor - the signaling clearly shows where exactly the problem occurred.

The platform also has warning lighting, similar to that used by forklifts, for example – flashing lights in the corners of the equipment and direction lights at the front and rear of the vehicle.

We started the installation at our location, significantly reducing the time required

Thanks to pre-assembly and testing of the equipment at our facility, the assembly time at the client's facility was significantly shortened. The platform truck worked after the first start-up. The implementation went smoothly, also thanks to the excellent communication with the customer, for which we would like to thank him. The full potential of the new equipment was thus available from day one, and we were delighted with the continued successful cooperation.

Are you curious about what else we have been working on? Check out other completed projects:

- A battery-powered transfer car moves 50 tons over a distance.

- Our transport platform rotates on the spot and does not need any rails.

- We have also created a device for automated dosing from big bags.